Cylinder heads are disassembled, and then cleaned both inside and out to remove all foreign matter.

We perform testing by magnetic partial crack detection, pressure test the coolant jacket and vacuum test or visual inspection of the valves and seats.

The head surface is cleaned and checked to ensure straightness and specification of thickness for allowance of resurfacing.

Valve guides are inspected for wear and guides which do not meet the original OEM specs may be service by replacement, re-machined or sleeved. Knurling is not an acceptable repair.

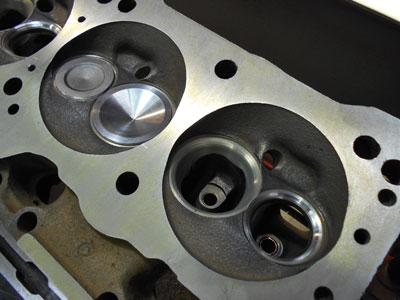

Valve seats are machined to retain the correct seat angles, widths, and valve heights. When seat recession is beyond limits new seat inserts are installed.

Valve face is re-machined and stems, keeper grooves, tips and valve margins are inspected and valves that do not conform to specifications are replaced. Cylinder head components, keepers, springs, retainers, rotators, etc. are inspected for serviceability and replaced where necessary.

Fuel injector sleeves are cleaned and checked and when appropriate replaced and machined to specifications. Pressure testing is then performed to verify sleeves are correctly sealed.

Cylinder heads with overhead camshafts will have camshaft bearing installed when bearing is worn or damaged by heat.